When the orifice gets a little damaged, poor angularity is the first thing you’ll notice, followed by more double arcs and more damage. This causes a double arc between the electrode and nozzle, and the nozzle and plate, which damages the nozzle orifice. If the nozzle touches the plate during a cut it creates a current path between the negative electrode, nozzle, and positive plate. Ideally, you need to hold a standoff with an unshielded setup at all amperages greater than 30 amps or so. The biggest problem with most plasma torches occurs when hand cutting with an exposed (unshielded) nozzle. However, if the operator understands good piercing and edge starting techniques to keep molten metal from blowing back onto the torch nozzle (or tip if a non-Hypertherm system) then consumable life can be extremely good. It’s hard to give an exact (or even in-exact) number as so many factors impact consumable life-operator experience, type and age of the torch, material type and thickness, air quality, etc. There’s also downtime to consider, not to mention the risk to your business or your brand.Īnswered by Jim Colt, Strategic Account Manager at Hypertherm® Poor quality cuts may require costly rework, and valuable equipment could be irreparably damaged. For starters, they do not last as long as genuine parts - often only a fraction of the cutting life. Those “low cost” counterfeit consumables can be a lot more expensive than they look. The use of unauthorized parts may also affect your warranty coverage. If unknown parts have been used in a damaged torch or plasma system, it will make troubleshooting difficult, if not impossible. The low quality metals used in counterfeit manufacturing may not be able to withstand the thermal demands of plasma cutting, putting equipment and, more importantly, may put operators at risk. Result: poor or inconsistent cuts, reduced cutting speed, and significantly shorter consumable life.

Any deviation from specified tolerances may impact overall performance.

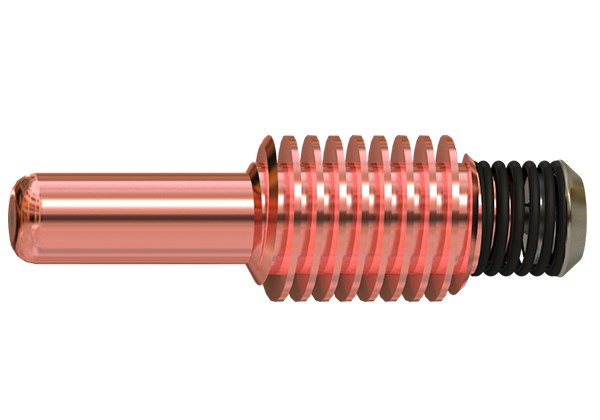

Plasma torches are precision devices requiring precision consumables. Their products are inferior, inconsistent, and unreliable. They use the lowest cost materials and the cheapest, fastest production techniques no stringent manufacturing processes, and no quality control. COUNTERFEITS Five reasons you should always buy genuine products through authorized distributors and avoid counterfeit products:Ĭounterfeit suppliers have one thought in mind: a quick profit. In some cases, the shield also contributes to the swirling action of the plasma gas. The main function of the shield is to protect and cool the other consumables, especially the nozzle from molten splatter. Highest quality – Investments in the most current quality systems, state-of-the-art manufacturing facilities and intensive machine operator training ensure that every consumable part that you receive from us will perform to your highest expectations. The specifications for these features are held to tolerance ranges that exceed even Six-Sigma quality standards. System features and consumable designs are matched to optimize performance and reliability – to give you the best possible cut, over the longest service life.Ĭritical to function engineering – Hypertherm® engineers identify the critical features of each consumable part that will have an impact on cutting performance, and design accordingly. Synergistic design – Hypertherm® systems and consumables are designed to work together. Thousands of hours of engineering time focused solely on plasma consumable technology guarantees the best possible cutting performance from your system.

Patented technologies – Every day, Hypertherm® engineers are working on new ways to improve the plasma cutting process. Protect your investment! Choose genuine torches and consumables for your Hypertherm® plasma cutting system and keep your system running at peak performance. Click here for the Installation Guide VideoĬlick here for a Powermax ® 45XP Cut ChartsĬlick here for a Hypertherm® 68/85/105 Reference GuideĬlick here for a Hypertherm® Inspection Chart GENERAL

0 kommentar(er)

0 kommentar(er)